Why Summer Fire Risk Increases in Factories | Industrial Prevention Guide India

Admin February 21, 2026 Why Summer Fire Risk Increases in Factories | Industrial Prevention Guide India Introduction Summer months pose...

Admin

February 21, 2026

Summer months pose elevated fire risks for factories and industrial facilities across India. Rising ambient temperatures, continuous machinery operations, and environmental dryness create conditions that significantly increase the probability of fire incidents.

Many industrial fires recorded during peak summer are not random events — they are often triggered by predictable, preventable factors.

Understanding these seasonal risks allows organizations to take proactive safety measures before accidents occur.

Industrial environments already contain multiple ignition sources. During summer, several stress factors amplify existing vulnerabilities:

✔ Higher equipment operating temperatures

✔ Increased electrical system load

✔ Faster evaporation of flammable substances

✔ Accumulation of dry combustible particles

Even minor safety lapses can escalate rapidly under extreme heat conditions.

Certain hazards become more dangerous during hot weather. The most frequently observed risk contributors include:

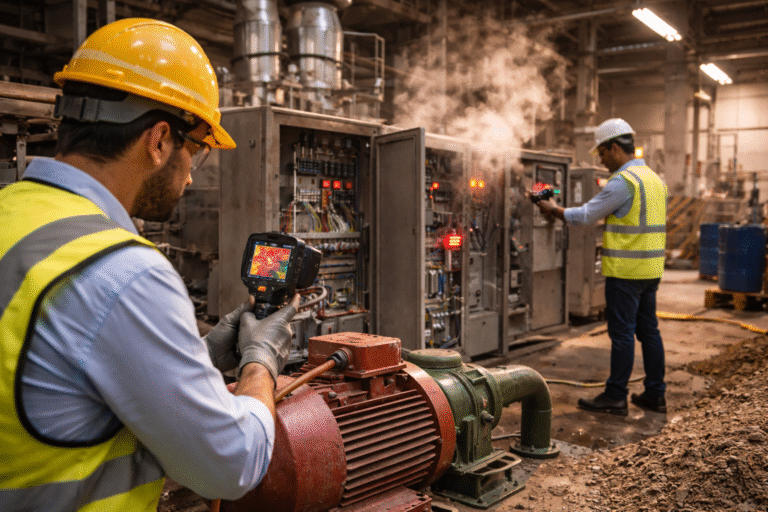

• Overheated motors and machinery

Continuous operation combined with poor ventilation may cause components to exceed safe temperature limits.

• Electrical overload and wiring stress

Cooling systems work harder in summer, increasing load on electrical circuits and panels.

• Chemical volatility and vapor formation

Heat accelerates evaporation of solvents and flammable liquids, increasing ignition probability.

• Dust and dry particle accumulation

Fine dust, fibers, and residues become highly combustible in dry conditions.

Summer-related fire risks are not always obvious. Commonly ignored contributors include:

Inadequate equipment cooling or airflow

Improper storage of heat-sensitive chemicals

Aging electrical insulation

Lack of preventive maintenance schedules

These latent issues often surface during extreme weather conditions.

Reducing summer fire risk requires a combination of technical checks and human awareness initiatives.

• Electrical load balancing and panel inspection

Prevents overheating, circuit stress, and short-circuit incidents.

• Cooling and ventilation system verification

Ensures motors, panels, and machinery operate within safe thermal limits.

• Employee fire safety awareness sessions

Helps staff recognize early warning signs such as unusual heat, odor, or equipment malfunction.

• Pre-summer fire audit and risk assessment

Identifies vulnerabilities before peak temperature periods.

Seasonal fire incidents are largely preventable. A structured fire safety audit helps organizations:

✔ Detect overheating risks

✔ Identify electrical system vulnerabilities

✔ Verify fire protection readiness

✔ Strengthen regulatory compliance

Proactive audits are far more cost-effective than post-incident recovery.

Summer does not create fire hazards — it intensifies existing ones.

Industries that prepare early through inspections, audits, and staff training significantly reduce accident probability and operational disruptions.

Preventive safety planning is an essential component of responsible industrial management.

Disclaimer:

This blog post is for informational purposes only and is not a substitute for professional fire safety advice. Always consult with experts for specific safety recommendations and guidance.

We hope you found this information helpful. Stay safe and be prepared!

Admin February 21, 2026 Why Summer Fire Risk Increases in Factories | Industrial Prevention Guide India Introduction Summer months pose...

Admin February 20, 2026 Fire Audit vs Fire Drill – Key Differences, Compliance & Safety in India Introduction In many...

Admin January 12, 2026 Fire Audit Services in Vadodara – Complete Industrial Compliance Guide (2026) Fire Audit Services in Vadodara...